Machines have evolved to meet the demands of daily life and industrial use, with molecular-scale devices often exhibiting improved functionalities and mechanical movements. However, mastering the control of mechanics within solid-state molecular structures remains a significant challenge.

Researchers at UNIST have made a groundbreaking discovery that could pave the way for revolutionary advancements in data storage and beyond. Jointly led by Professor Wonyoung Choe and Professor Seung Kyu Min in the Department of Chemistry at UNIST, a team of scientists has developed zeolitic imidazolate frameworks (ZIFs) that mimic intricate machines. These molecular-scale devices can exhibit precise control over nanoscale mechanical movements, opening up exciting new possibilities in nanotechnology.

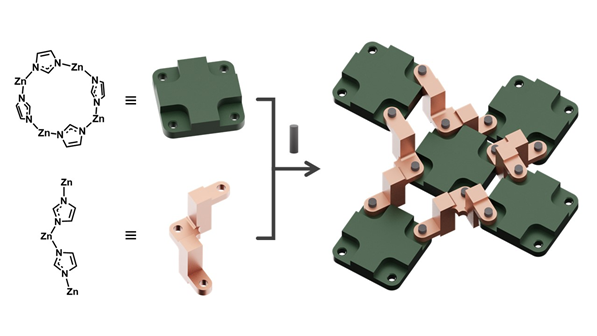

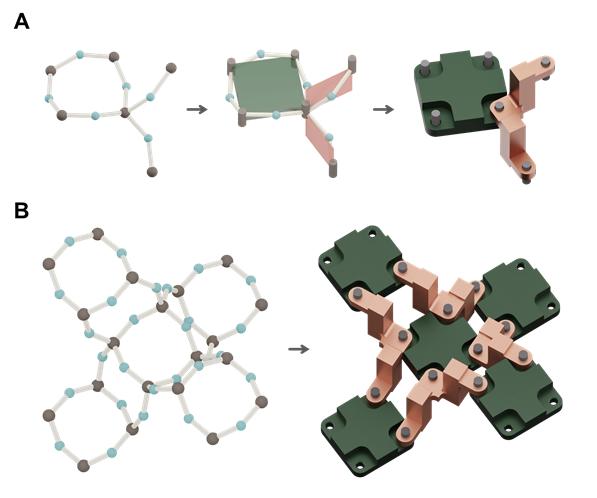

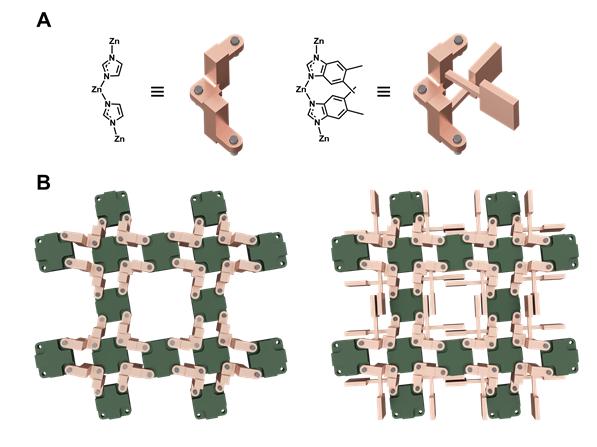

To engineer these solid-state nanoscale machines, metal–organic frameworks (MOFs) were used as a foundation, integrating molecular machines as mechanical components into already developed structures. A recent significant example involved embedding multiple dynamic components within a MOF as pillared ligands, which maintained the rotational motion of the embedded machinery in a solid state. Historically, linking machine-like behavior in MOFs with their mechanical properties has been rare because MOFs have not inherently shown such behaviors.

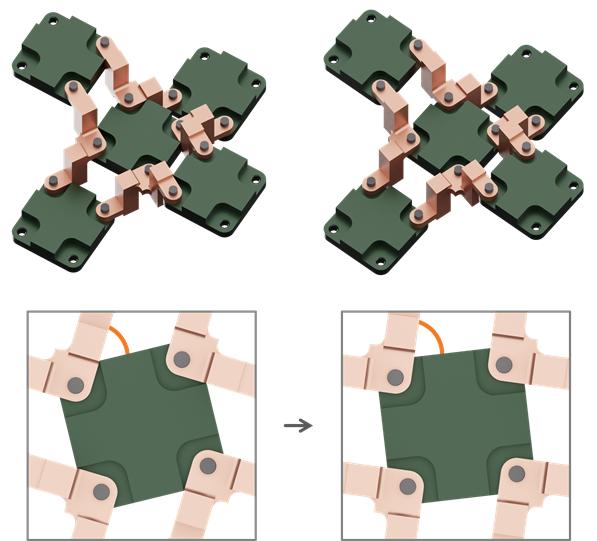

The team used single-crystal X-ray diffraction to verify that the linkage structure of the ZIF resembles that of a mechanical linkage. This particular ZIF operates on the principle of a slider-crank linkage, which translates rotational motion into linear motion, responsive to temperature changes and solvent molecules. By swapping out the mechanical parts of the solid-state molecular machine, they achieved precise control of nanoscale movements. The researchers also discovered that this machine exhibits the highest elasticity and flexibility among other ZIFs, making it an ideal candidate for applications in data storage and beyond.

The research team concluded that the unique mechanical properties are primarily due to the mechanical linkage structure of the ZIF. Structures made from the same metal nodes and organic ligands show different levels of flexibility depending on how they are connected. This characteristic, crucial for machines that need to assemble components in various ways to achieve specific movements, is expected to drive the development of innovative nanomaterials.

“Implementing machine-like movements at the molecular level opens the door to discovering new materials with unique mechanical properties,” explained Professor Wonyoung Choe. “Our research into various molecular mechanical components and mechanical linkage structures is setting the stage for future applications in areas, such as digital data storage, where precision control over mechanical movements is crucial.”

The findings of this research have been published and selected as Hot Paper in Angewandte Chemie International Edition, on June 14, 2024. This study has been supported by the National Research Foundation (NRF) of Korea via the Mid-Career Researcher Program and Hydrogen Energy Innovation Technology Development Project, and by the Korea Planning & Evaluation Institute of Industrial Technology (KEIT), as well as the Carbon Neutral Institute Research Fund, funded by UNIST.

Journal Reference

Joohan Nam, Seokjin Kim, Eunji Jin, Soochan Lee, Hye Jin Cho, Seung Kyu Min, and Wonyoung Choe, “Zeolitic Imidazolate Frameworks as Solid-State Nanomachines,” Angew. Chem. Int. Ed., (2024).